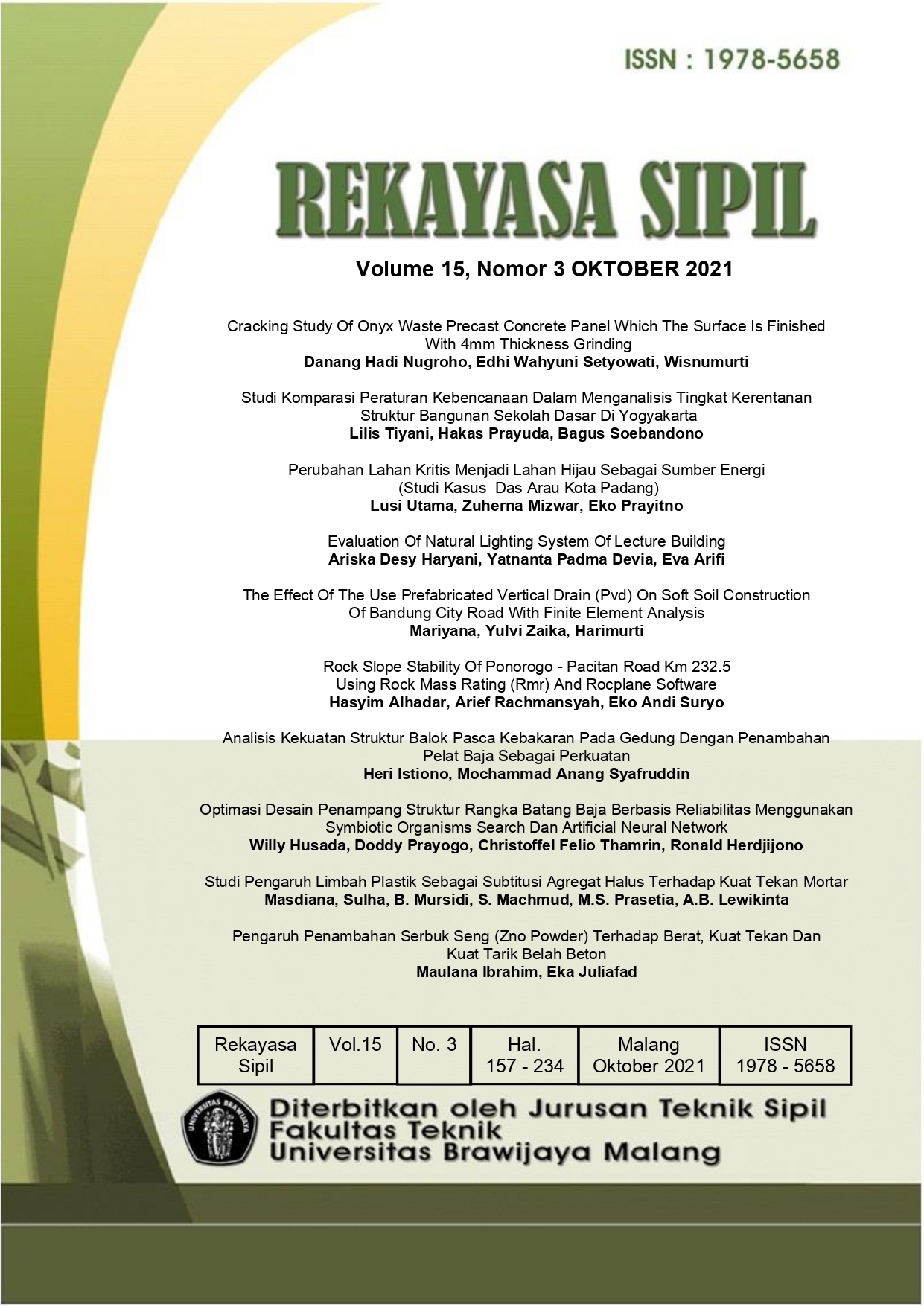

CRACKING STUDY OF ONYX WASTE PRECAST CONCRETE PANEL WHICH THE SURFACE IS FINISHED WITH 4MM THICKNESS GRINDING

DOI:

https://doi.org/10.21776/ub.rekayasasipil.2021.015.03.1Keywords:

concrete, cracks, grinding, onyx, panels, precastAbstract

This research is a continuation of a series of research on Tulungagung onyx waste. The large volume of onyx waste in the area around the Tulungagung onyx processing plant is used as a substitute for gravel aggregate in the concrete mixture which is processed into exposed concrete which has high aesthetic value. In this study, a finishing treatment process (panel thickness thinning) was carried out which aims to produce coarse aggregates from the walls of the onyx concrete waste panels as exposed concrete which has high aesthetic value. The researcher wanted to know the cracking behavior of the onyx concrete waste panel walls before and after the finishing process. The test object used is the test object of previous researchers, namely the wall of the onyx waste concrete panel size 80 cm x 40 cm x 6 cm with practical steel reinforcement Ø6 - 100 mm attached, so that in this study the researcher only carried out the finishing treatment of panel thickness thinning, in-plane three-point loading test and took data on the cracks that occurred. The result of the finishing process by grinding of 2 mm shows that the percentage of aggregate is seen on average 1.8% of the total surface area, while for the finishing of 4 mm it shows that the percentage of aggregate is seen on average 35%. No initial cracks were found on the surface of the specimen after grinding 2 mm or 4 mm. The cracks experienced after loading were flexural cracks, where all the samples had only one crack in the direction almost perpendicular to the panel axis. The bending stress that occurs in the panels during the initial cracking of the non-grinding panels, 2 mm grinding panels, 4 mm grinding panels is 4.75 MPa, 4.62 MPa, 4.60 MPa respectively.References

Setyowati, E.W., Agoes Soehardjono, & Wisnumurti. 2017. Concrete With Onyx Waste Aggregate As Aesthetically Value Structural Concrete. AIP Conference Proceedings 1887, 020013

Khosemde, A.N., Edhi Wahyuni Setyowati, dan Wisnumurti. 2016. Pengaruh Penggunaan Limbah Batu Onyx Sebagai Pengganti Agregat Kasar Pada Campuran Beton Terhadap Porositas Beton : Jurnal Mahasiswa Jurusan Teknik Sipil.

Setyowati, E.W. 2016. Kuat Tekan Beton Limbah Batu Onix Tulungagung. Media Teknik Sipil, 14(2), 140-146.

Setyowati, E.W., Ari Wibowo. 2003. Teknologi Beton. Malang : Buku Diktat

Rahmawati P, D. R., Setyowati, E. W., & Anggraini, R. 2016. Pengaruh Penggunaan Limbah Batu Onyx Sebagai Pengganti Agregat Kasar Pada Campuran Beton Terhadap Kuat Tekan Beton. Jurnal Mahasiswa Jurusan Teknik Sipil, 1(1), pp-151.

Ghiyats, A. 2016. Pengaruh Penggunaan Limbah Batu Onyx Sebagai Pengganti Agregat Kasar Pada Campuran Beton Terhadap Modulus Elastisitas Beton : Jurnal Mahasiswa Jurusan Teknik Sipil.

Hatta, M.N., 2006. Uji Kuat Lentur Dinding Panel Hardflex dan Styrofoam Dengan Tulangan Bambu : Tugas Akhir, Jurusan Teknik Sipil, Fakultas Teknik, Universitas Muhammadiyah Surakarta.

Mangunwijaya, Y. 1981. Pasal - Pasal Penghantar Fisika Bangunan (2nd ed.). Jakarta: PT Gramedia.

TRB. 2006. Control of Cracking in Concrete, State of the Art. Circular Transportation Research. Transportation Research Board, Basic Research and Emerging Technologies Related to Concrete Committee.

Amri, S. 2005. Teknologi Beton A-Z. Jakarta : Yayasan John Hi-Tech Ideatama

McCormac, J.C. 2001. Desain Beton Bertulang. Edisi Kelima. Jakarta : Erlangga.

Nawy, Edward G. 2010. Beton Bertulang, Suatu Pendekatan Dasar. Terjemahan Ir. Bambang Suryoatmono, M.Sc. Bandung: PT Refika Aditama

Fathallah, B.B., Fredj, N.B., Sidhom, H., Braham, C. dan Ichida, Y. 2009. Effects of Abrasive Type, Cooling Mode and Peripheral Grinding Wheel Speed on the AISI D2 Steel Ground Surface Integrity. Int. J. of Mach. Tools & Manufacture, Vol. 49, pp. 261-272

Lee, H.T. dan Tai, T.Y. 2003. Relationship between EDM Parameters and Surface Crack Formation. Journal of Materials Processing Technology, Vol. 142, hal. 676-683

Kotsovos M. D., Salek M.S., Milija N.Pavlović. 1992. Experimental Study Of The Compressive-Force Path Concept In Prestressed Concrete Beams. Department of Civil Engineering, Bangladesh University of Engineering and Technology, Dhaka, Bangladesh

Mahmud, Edhi Wahyuni Setyowati, & Agoes Soehardjono. 2018. Pengaruh Proses Finishing Terhadap Kuat Lentur Dinding Panel Beton Onyx : Jurnal Mahasiswa Jurusan Teknik Sipil.

Park, R and Paulay, T. 1975. Reinforced Concrete Structures. New York City: John Wiley & Sons, Inc.

Suprayitno, E. F. 2018. Pengaruh Limbah Batu Onyx Sebagai Pengganti Agregat Kasar Beton Terhadap Kuat Lentur Balok Beton Bertulang. Jurnal Mahasiswa Jurusan Teknik Sipil, 1(2), pp-934.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Rekayasa Sipil

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

This journal is licensed under a Creative Commons Attribution 4.0 International License